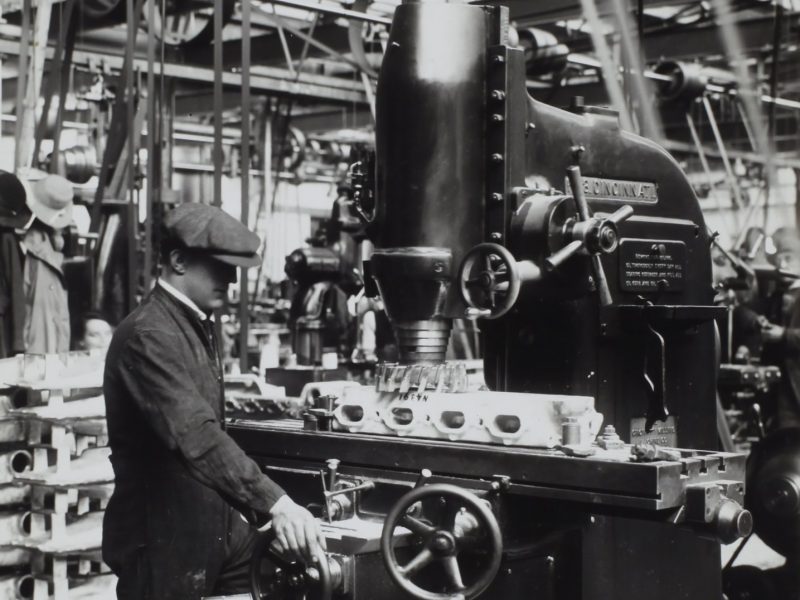

Back comes the Bentley

What an iconic form this vehicle is yet it’s modernised for today’s world.

The Bentley Blower has completed a 6 hour endurance test at full race pace at Goodwood which reportedly resulted in a ‘flawless performance’.

Car Zero as it’s called is part of the Continuation Series that’s ready for the race track.

The earlier mentioned test has proven the quality of the engineering for this model but has also given the team learnings to take into the build of the first engineering car which is already being completed.

In 1923 Bentley had a car in the Le Mans race, how amazing to see this new model in today’s news!