What are you designing for?

This is a critical question.

What do you want designing doesn’t provide enough to start a project; even though it’s important stuff to start off with.

The angle of the question ‘what are you designing for’ is more about whether it’s a concept or you’re ready to move on from that stage to designing for manufacturing.

Let’s move through the conceptual designs.

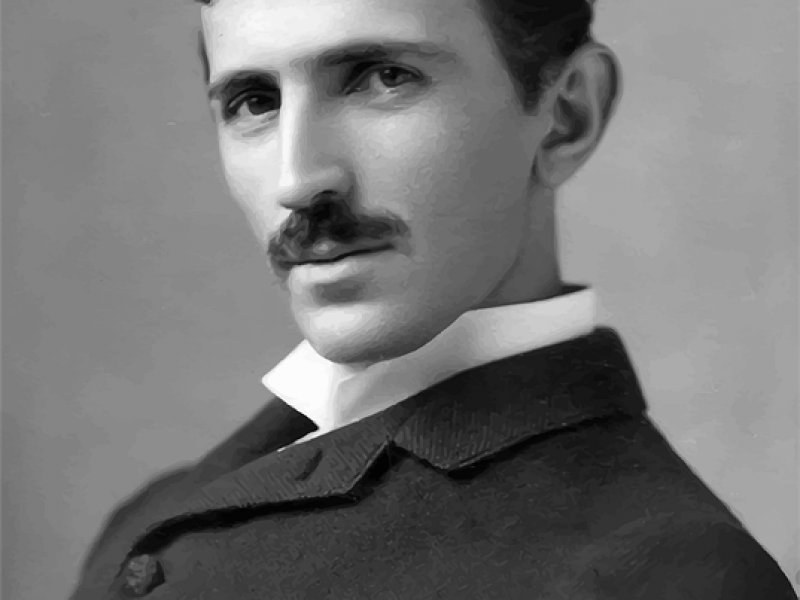

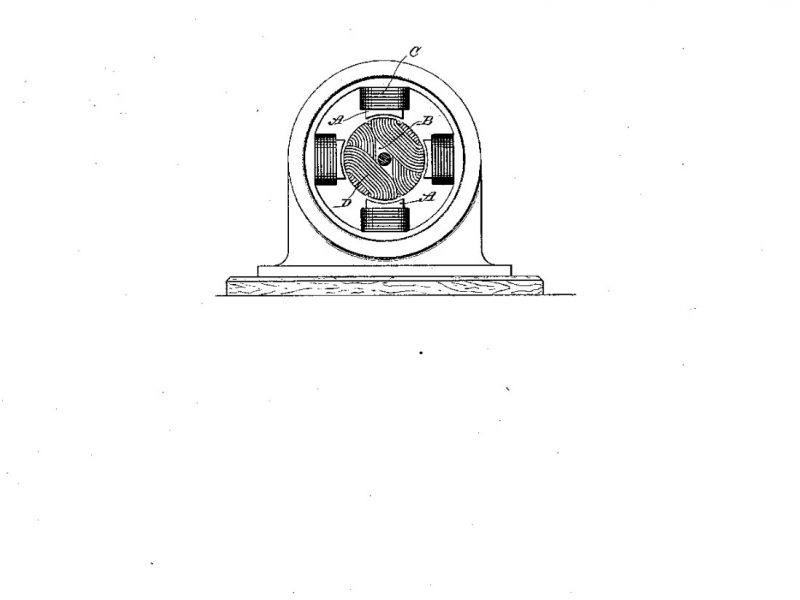

Back in 1889 Nikola Tesla designed and then patented the Electric Motor. It was model number 416,194 that was patented in that year. This AC induction motor was a two-phase pulsation which other engineers did not deem feasible. It was feasible and practical engine was created by the engineer George Westinghouse in 1892.

The thing is Tesla was very much a conceptual designer; ‘he conducted a range of experiments with mechanical oscillators/generators, electrical discharge tubes, and early X-ray imaging.’*

Not everything he designed would have moved away from the concept stage.

Often a concept is needed to see if the idea is valid. It’s a way to present to clients to see if your idea will solve a challenge or is the right thinking for putting their idea into practise.

What’s the difference with design for manufacturing?

- Sizes, actual real sizes for the thing being designed.

- Setting, where is the thing going to be located (if it’s plant equipment for example).

- Tolerances, those exact dimensions specified accurately.

- Materials, what will work in the operating environment or is the most robust material required.

- Specifications, how will parts fit together.

- Conditions, is there lots of dust or does the environment have temperature fluctuations.

- Solved, is the design solving the real issue that needed to be addressed.

When creating a manufacturing drawing it’s essential that every single little detail is captured. It means the difference between something work or not. It’s ensuring every angle has been reviewed, not the degree type angles (although they are super important too!) but ensuring full conversations and site inspections have been had.

Here at Bennett Engineering we’re proud that over 95% of the designs for manufacture actually get manufactured.

It means all bases and angles have been covered. It means that concepts have been moved on to installation or creation. It’s the natural progression of the journey.